Custom Butter Paper In Canada

Design Custom Butter Paper In Canada

Get an Instant Quote

Free Artwork

Biodegradable & Recyclable

Fastest Turnarround

Renewable Plant Based Material

Free Delivery

Custom Butter Paper Sheets & Rolls In Canada

When it comes to baking and lining, one thing that certainly comes to mind is butter paper. Its smooth surface, grease-resistant ability, and sturdiness make it one of the most crucial components of baking. At commercial levels, in addition to using the paper as a pa liner, brands use it to wrap their foods with high-fat content as this paper is impervious to grease and prevents the creation of mess.

In addition, if you use printed butter paper with the logo of your brand, then you can get the best and most economical option to promote your brand and get the customers’ attention. At our company, you can find high-quality butter paper and elegant printed designs at lower rates.

Types Of Butter Paper That We Have In Canada

Today’s technology has advanced significantly, making it possible to offer the best products and services. The same applies to the custom packaging industry. And the packaging industry is not free from it. We have got you covered if you are among the brands selling food and new custom food wraps with custom sizes and designs. We have multiple types of butter paper sheets based on how much they withstand moisture, the type of coating, and the type of printing. Some of the options are:

- Standard Butter Paper

- Wax-Coated Butter Paper.

- Silicone-Coated Parchment Paper

- Glassine Butter Paper

- Printed Butter Paper

Manufacturing Process Of Butter Paper

The manufacturing process of butter paper is complex. To give it its unique properties several steps are followed, from the pulping of the wood fibers to applying coatings. All the processes are done chronologically to get the best quality butter paper for baking. The steps that we follow are:

Pulp Preparation

The first step we follow is the preparation of pulp, for which we use softwood fiber because it is rich in cellulose and helps create sustainable packaging solutions. We remove all the residues from the pulp and apply bleaching agents to remove the natural brown color of the pulp. With the help of both these processes, butter paper rolls of suitable consistency are produced.

Chemical And Mechanical Processing

To give the pulp the desired surface, sturdiness, and size, we use several chemical and mechanical processes that provide the custom paper’s most refined quality. The chemical method involves the treatment of the paper with sulphuric acid. This treatment gives the paper transparency and resistance to moisture. On the other hand, in the mechanical process, we grind and refine the paper to provide a uniform and delicate texture.

Sheet Forming

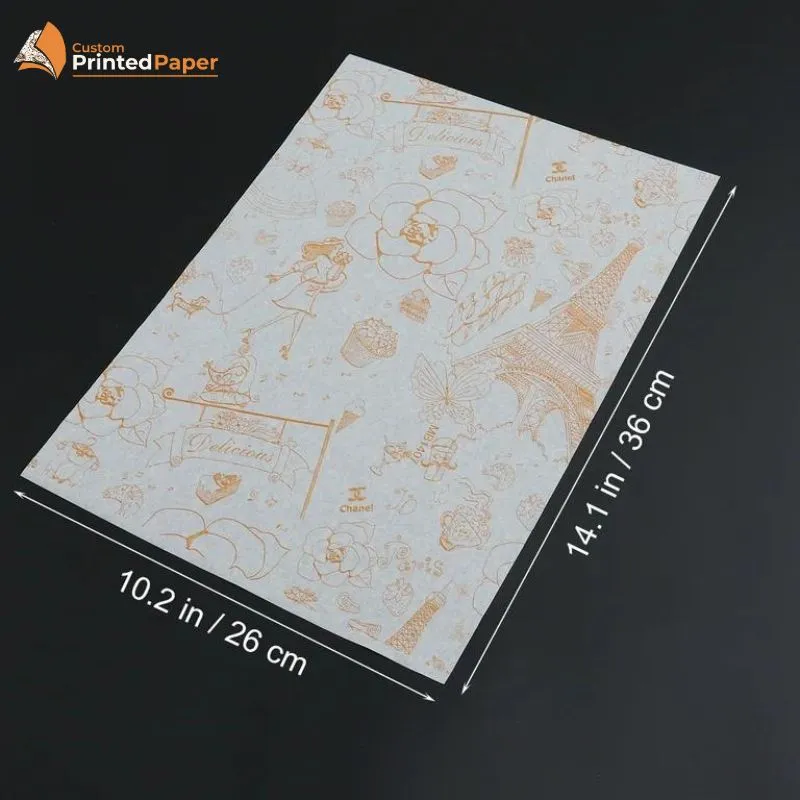

To get butter paper sheets, we spread the pulp onto a mesh so that the extra water drains through it and the paper receives the desired thickness and texture. The variation in the thickness of the sheets allows the customers to choose the best option, considering their intended use.

Coating Process

We apply different coatings to give a smooth and shiny surface like custom wax paper to the sheets; the coatings’ types decide the paper’s nature. If you opt for wax coatings, it may not withstand high temperatures. On the other hand, if you get silicone coatings, the paper can withstand significantly high temperatures. The coatings on either one or both sides of the paper give non-stick and grease-resistant properties.

Drying and Curing

After the coatings application, custom butter paper is cured and dried so that the chemical and mechanical properties of the coatings are set on the paper. This step is essential to impact the paper and its unique properties.

Cutting And Rolling

We have all the options available from sheet to roll at your service. You can select rolls if you do not want to get a specific size of the paper, and if you’re going to get pre-cut sheets, then you can give us the size you wish to the paper so that we can apply the printed design accordingly.

Chemicals Used In Manufacturing

As butter paper manufacturers, we apply several chemicals to the paper to enhance its functionality. We make sure that no residual chemicals remain in the sheets. That is why we thoroughly wash and then dry the sheets. The chemicals that we use are:

- Sulfuric Acid

- Wax or Paraffin

- Silicone

We use these chemicals in controlled amounts and food-grade quality so that the paper remains perfect for direct use with the food items.

FSA And FDA Approval Status

Food uses of butter paper are governed by either the FSA or FDA because butter paper is commonly used to pack and prepare food products. Regulations with these agencies are crucial so that butter paper is acceptable for use with food products.

FDA Approval: FDA-approved butter paper went through various tests to ensure it is safe and does not come into contact with any poisonous substance. Butter paper must obtain FDA approval as a product sold in the United States, and it is a clear sign of product quality.

FSA Compliance: Besides, butter paper can be compliant with the Food Safety Authority (FSA), mainly if the product is to be sold in the European continent. FSA compliance confirms that the food product complies with the legal requirements of the EU in terms of maximal trace levels of contaminants and prohibited and restricted use of additives and processing aids.

ISO Certification

This ISO requirement also proves the quality and standard of the manufacturing processes. Many butter paper manufacturers adhere to ISO standards, particularly:

ISO 9001: This certification is evidence of compliance with quality management systems and constant production quality.

ISO 22000: Where one finds manufacturers who supply food-grade butter paper, there may be ISO 22000 certification in adherence to global food safety standards.

Certification with ISO standards has the added advantage of bringing civilization and customer confidence in quality products and service delivery.

Printing

We have one of the finest and highest-quality printing facilities for custom-printed butter paper. Our printing colors are food-grade and free from any contamination and toxins. Like the paper, the colors FDA and FSA also approve the colors so that you can wrap food or liner pans without hesitation. Using butter paper with logos, you can easily promote the brand and increase the market value of the product due to its professional appearance.

| Section | Details |

| Types of Butter Paper | 1. Standard Butter Paper

2. Wax-Coated Butter Paper 3. Silicone-Coated Parchment Paper 4. Glassine Butter Paper 5. Printed Butter Paper |

| Manufacturing Process | Steps include pulp preparation, chemical and mechanical processing, sheet forming, coating process, drying and curing, cutting and rolling. |

| Pulp Preparation | Uses softwood fiber, bleaching agents for consistency, and cellulose for sustainable packaging solutions. |

| Chemical and Mechanical Processing | Sulfuric acid for transparency and moisture resistance, grinding for a delicate texture. |

| Sheet Forming | Pulp spread on mesh to drain extra water and form sheets with varying thickness for customer selection. |

| Coating Process | Coating options include wax or silicone for smooth, non-stick surfaces. Silicone withstands high temperatures better. |

| Drying and Curing | Essential for setting the chemical and mechanical properties of coatings. |

| Cutting and Rolling | Available in rolls or pre-cut sheets. Custom sizes and printed designs can be provided. |

| Chemicals Used | Sulfuric acid, wax or paraffin, and silicone are used in controlled amounts, ensuring food-grade quality. |

| FDA and FSA Approval | FDA approval ensures safety for use with food products in the U.S., while FSA compliance is necessary for European markets. |

| ISO Certification | ISO 9001 for quality management and ISO 22000 for global food safety standards. |

| Printing | High-quality, food-grade printing colors, FDA and FSA-approved, used for custom butter paper designs and brand promotion. |

Call Us Now!

Contact CustomPrintedPaper If you want high-quality, food-grade custom butter paper. We manufacture food wraps with the exact specifications the customer requires, so call us now and get what you want.

| 4" x 4" | 5" x 5" | 6" x 5" | 6" x 6" |

| 7" x 5" | 7" x 7" | 8" x 5" | 8" x 6" |

| 8" x 8" | 8.5" x 11" | 9" x 5" | 9" x 6" |

| 9" x 9" | 10" x 5" | 10" x 6" | 10" x 8" |

| 10" x 10" | 10.75" x 10" | 12" x 6" | 12" x 8" |

| 12" x 9" | 12" x 10" | 12" x 12" | 13" x 6" |

| 13" x 9" | 13" x 10" | 13" x 13" | 14" x 12" |

| 15" x 9" | 15" x 10.75" | 15" x 12" | 15" x 13" |

| 16" x 12" | 17" x 11" | 18" x 10" | 18" x 12" |

| 18" x 13" | 20" x 10" | 20" x 12" | 20" x 13" |

| 20" x 15" | 20" x 18" | 20" x 20" | 20" x 25" |

| 20" x 28" |

Frequently Asked Questions

Q: What is the shelf life of butter paper?

You can use the paper for 1 to 2 years of manufacturing if you have saved it properly.

Q: Is it safe to use butter paper in the microwave?

Yes, you can use the paper without the fear of burning.

Q: Can I use the paper in the ovens?

It depends upon the type of coating you choose. If you have chosen a wax coating, do not use it in the oven, and if you have chosen a silicone coating, it is safe to use the paper in the oven.

Q: What is the benefit of using FSC-approved custom butter paper?

By using FSC-approved materials, your company can reduce its carbon footprint, as FSC-approved materials are obtained from sustainably managed woods.

Product

Highlights

How We Manufacture

Custom Printed Paper

We manufacture all the custom food wraps with premium quality, FSC, and FDA-approved paper to ensure your product safety, presentation, and brand promotion. With the endless possibilities of paper dimension and unique, yet high-quality coatings, we provide you with the best and the most affordable wraps.

Moreover, we give our customers to decorate their paper in any way by opting for the option of designing an online tool where you can take charge of the final look and dimensions of the paper. Our custom food wraps are oil and moisture-resistant so are an excellent option for long-term retention of food quality without much investment.

Get a QuoteWhat makes us different

Premium service you won't experience with other providers

Speed

Our overall manufacturing facilities for custom printed papers are fast and give premium results. It takes us only 6 to 8 business days to complete your order and deliver it to your doorstep.

Quality

The quality of our custom printed paper is premium and after processing the raw material, we give accurate design with minimum chances of error. We have micro scanners that scan each specification of custom printed paper for consistency.

Range

We have a wide range of paper types that include custom deli paper, wax paper, custom greaseproof paper, and much more. Moreover, you do not need to worry about the dimensions as we have standard to custom options for this.

Sustainable Solutions

We use high-quality kraft material and apply the relevant coating on it. Apart from paraffin wax, all our coatings are sustainable, even though we have a sustainable alternative too which is beeswax.

Innovation

Our company believes in innovation and strives for continual improvement which is why all our manufacturing facilities are avant-garde, unique, and highly efficient. These facilities help us in giving the best and the most accurate results.

Cost Savings

Considering the client's budget and understanding the customer's preference, our custom printed paper is a perfect blend of quality and cost-effectiveness. As we have all in-house manufacturing facilities that is why we easily cap the end cost of the product and deliver you at affordable rates.