Custom Burger Wrapping Paper

Design Custom Burger Wrapping Paper

Get an Instant Quote

Free Artwork

Biodegradable & Recyclable

Fastest Turnarround

Renewable Plant Based Material

Free Delivery

You can easily find lovers of burgers all around the globe and from all age groups. The availability of different flavors and the handy nature of burgers make them famous. In addition to the taste of the burgers, the presentation contributes to their high sales. Getting custom burger wrapping paper allows you to give the best presentation to the burgers.

This paper gives the burgers an excellent presentation while protecting them from all contaminants. In addition, with the availability of custom printing services, many brands use this paper to promote their brands and increase their market presence.

Our company manufactures custom burger wrapping sheets in CA with unique and alluring artwork as customers require. Our custom manufacturing facilities allow food-related businesses to give their food items a personalized look without much investment, and we also provide wholesale rates.

Key Benefits Of Custom Burger Paper In Canada

If you are new in the food business or have just started your food corner, you must face difficulty getting customers’ attention. Today, customers not only prefer taste but also pay attention to the presentation of the product, and custom burger paper wrappers will help you in this regard. Some of the key benefits that you can get by investing in this paper are:

- Branding Opportunities

- Functional Advantages

- Eco-Friendly Options

- Cost-effectiveness

- Elegant presentation and perfect protection

Manufacturing Process

To ensure the quality and the overall look of custom food paper for burgers, we follow a series of steps that make it easy to manufacture the most professional-looking and high-quality paper. Not only this, but we also consider the branding requirements of your products and make sure to incorporate the design and logo of your company with the perfect alignment. For the manufacturing of personalized burger wrapping paper Canada, we use the following steps:

Raw Material Selection

Raw material is one of the main requirements for a high-quality custom paper. For this, we choose kraft paper obtained from softwood fibers. This paper is sustainable and easy to compost, making it ideal if you want to lessen your company’s ecological footprint.

Pulping

In this step, we produce the pulp of the raw material to eliminate all the impurities. The fiber is broken down to give the paper a smooth surface area. Whether mechanical or chemical pulping is required depends on the desired properties of the paper.

Forming The Paper

To convert the pulp into sheets, we spread the pulp onto a large screen. The thickness and density of burger wrapping paper are controlled to achieve the required strength and absorbency. This step is crucial as it removes all the excess water and acquires a fine paper sheet. After this, the formed sheets are dried with the help of heated rollers or air dryers to achieve a flexible paper sheet.

Coating

Coating is an optional feature that you may or may not opt for for the paper. Different coatings are available in the market; for example, we apply wax coating if you need a surface like custom wax paper. On the other hand, if you want to keep the rustic look of the paper intact, then you can go without coatings and so on. Coatings are essential in determining the characteristics and functionality of custom burger wrapping paper, such as by enhancing moisture resistance, grease resistance, and printability. You can get the following types of coating from us:

Grease-Resistant Coatings

These coatings prevent grease from seeping through or penetrating the paper and hence help avoid a mess. If you want greaseproof paper to wrap your burgers, this is the best option. These coatings keep the paper clean and enhance durability. In it, we use:

- Polyethylene (PE)

- Paraffin wax

- Bio-based coatings.

Moisture-Resistant Coatings

Moisture-resistant coatings ensure the paper’s structure remains intact even if you wrap a juicy burger in your custom burger paper sheets. These coatings prevent the burgers from getting soggy and retain the crunchiness of your food.

- Silicone-based coatings

- Wax emulsions

Eco-Friendly Coatings

Today sustainability is becoming increasingly important, and all brands are incorporating this into their products and packaging to reduce solid waste. Considering this, we are giving eco-friendly coating for all the food wraps such as burgers, sandwiches, and deli papers. These coatings retain the sustainable aspect of the paper, help you reduce the environmental impact, and allow you to comply with the green standards.

- Bio-based polymers

- Water-based coatings.

| Coating Type | Materials Used | Primary Function | Benefits |

| Grease-Resistant | PE, paraffin wax, bio-based | Prevents grease penetration | Maintains paper cleanliness, durability |

| Moisture-Resistant | Silicone-based, wax emulsions | Protects against water-based liquids | Prevents sogginess, strengthens paper |

| Printable | Clay, calcium carbonate | Enhances surface for printing | Sharp, vibrant designs, high print clarity |

| Eco-Friendly | Bio-based polymers, water-based | Reduces environmental impact | Sustainable, aligns with green standards |

Cutting And Shaping

The customer must provide us with the dimensions they want to get the desired shape and size of burger paper liner packaging. From pre-cut sheets to large rolls, we have all the options for you.

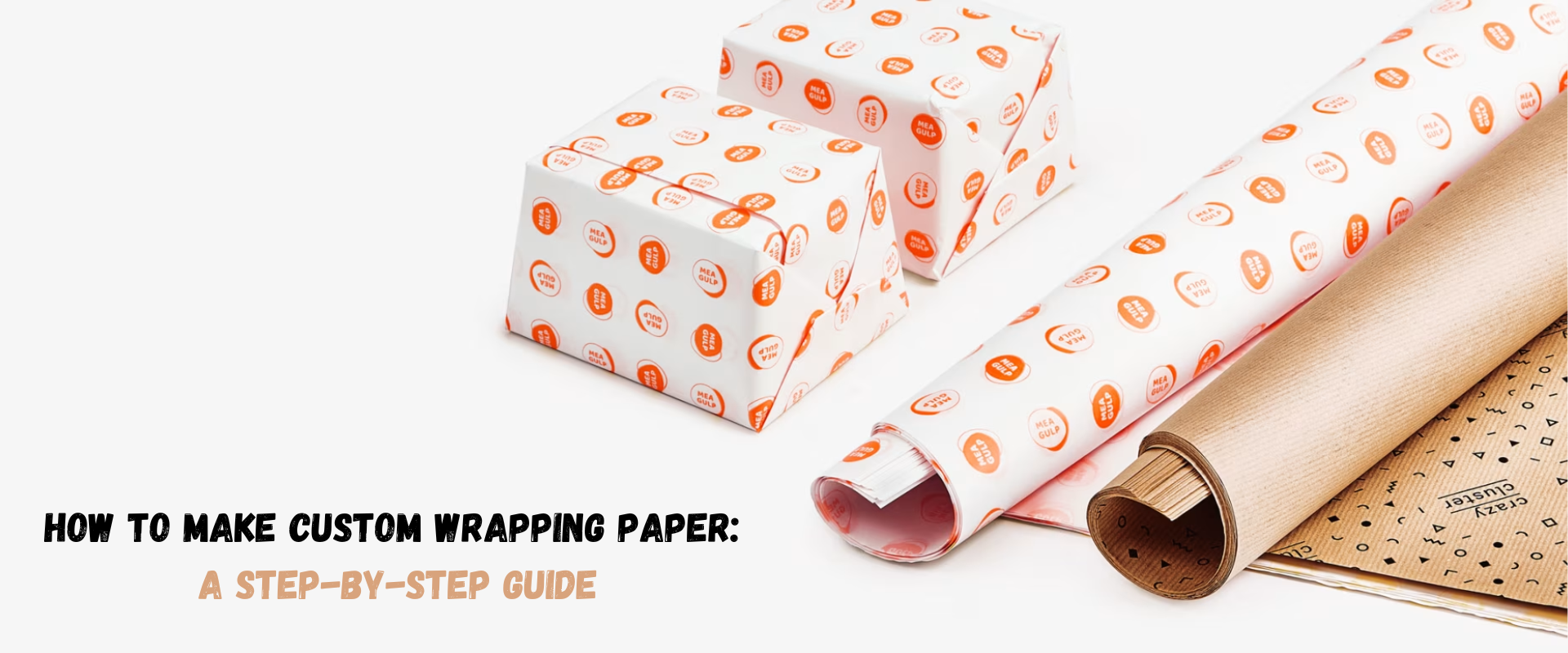

Printing

Printing is one of the most essential components of customization. Custom printed burger wrapping paper allows you to give the paper an elegant and attractive look and get the maximum attention from the customers. In addition, by selecting the option of logo printing, you can get an effective promotional tool for your company. We have the following options to give a burger wrapping paper design that can allure your targeted audience:

- Offset printing

- Flexography

- Screen printing

- Digital printing

| Step | Description | Key Considerations |

| Raw Material Selection | Choosing paperboard or Kraft paper | Recycled vs. virgin materials |

| Pulping | Breaking down materials into fibers | Mechanical vs. chemical pulping |

| Forming the Paper | Creating sheets from pulp | Thickness and density control |

| Drying | Removing moisture from sheets | Drying method efficiency |

| Coating (Optional) | Adding moisture-resistant layers | Type of coating used |

| Cutting and Shaping | Precision cutting into sizes and shapes | Die-cutting accuracy |

| Printing | Applying custom designs | Printing technique suitability |

| Quality Control | Ensuring consistency and quality | Inspection methods |

| Packaging | Preparing for distribution | Packaging materials and methods |

Chemicals Used In Custom Printed Burger Paper

We use different types of chemicals on custom burger wrapping paper. The substances are entirely free from hazardous elements and are food-grade. They are necessary to enhance the paper’s functional properties. For burger wrapping paper printing, we have to use different inks, but we prefer food-grade inks only that are allowed by the FDA. The table below contains the various types of chemicals that we use on paper.

| Chemical Type | Purpose | Common Types | Safety Considerations |

| Sizing Agents | Grease and moisture resistance | ASA, wax emulsions | FDA-compliant, food-safe |

| Bleaching Agents | Achieve color and brightness | Chlorine dioxide, H₂O₂ | Preference for chlorine-free |

| Coating Chemicals | Enhance surface properties | PE, paraffin wax | Must be food-grade |

| Additives for Strength | Improve durability and flexibility | Starches, latex binders | Non-toxic, approved for food contact |

| Printing Inks | Apply custom designs and branding | Soy-based, water-based inks | Non-toxic, food-safe |

Applications

If you are running a restaurant, then you must want to get a tool that can enhance the promotion of your restaurant without breaking the bank. You must also want to give a safe and elegant food presentation. If so, then custom burger paper is the best option for you. You can use the paper for various purposes, such as:

| Application | Description | Benefits |

| Burger Wrapping | Securely wrapping burgers for transport and display | Maintains burger integrity and appearance |

| Presentation Enhancement | Enhancing visual appeal with unique designs and colors | Attracts customers, improves dining experience |

| Branding and Marketing | Imprinting logos, slogans, and promotional messages | Reinforces brand identity, mobile advertising |

| Sustainability Initiatives | Utilizing recycled or compostable materials | Appeals to eco-conscious consumers |

| Seasonal Promotions | Reflecting seasonal themes or limited-time offers | Creates exclusivity, drives urgency |

Call Us Now!

If you are looking for the best and the most economical option to get custom burger wrapping paper, then look no further and invest in Custom Printed Paper. We provide a holistic approach to the wrapping of burgers and the promotion of the brand in one custom wrap, so call us now and get yours!

| 4" x 4" | 5" x 5" | 6" x 5" | 6" x 6" |

| 7" x 5" | 7" x 7" | 8" x 5" | 8" x 6" |

| 8" x 8" | 8.5" x 11" | 9" x 5" | 9" x 6" |

| 9" x 9" | 10" x 5" | 10" x 6" | 10" x 8" |

| 10" x 10" | 10.75" x 10" | 12" x 6" | 12" x 8" |

| 12" x 9" | 12" x 10" | 12" x 12" | 13" x 6" |

| 13" x 9" | 13" x 10" | 13" x 13" | 14" x 12" |

| 15" x 9" | 15" x 10.75" | 15" x 12" | 15" x 13" |

| 16" x 12" | 17" x 11" | 18" x 10" | 18" x 12" |

| 18" x 13" | 20" x 10" | 20" x 12" | 20" x 13" |

| 20" x 15" | 20" x 18" | 20" x 20" | 20" x 25" |

| 20" x 28" |

Frequently Asked Questions

Product

Highlights

How We Manufacture

Custom Printed Paper

We manufacture all the custom food wraps with premium quality, FSC, and FDA-approved paper to ensure your product safety, presentation, and brand promotion. With the endless possibilities of paper dimension and unique, yet high-quality coatings, we provide you with the best and the most affordable wraps.

Moreover, we give our customers to decorate their paper in any way by opting for the option of designing an online tool where you can take charge of the final look and dimensions of the paper. Our custom food wraps are oil and moisture-resistant so are an excellent option for long-term retention of food quality without much investment.

Get a QuoteWhat makes us different

Premium service you won't experience with other providers

Speed

Our overall manufacturing facilities for custom printed papers are fast and give premium results. It takes us only 6 to 8 business days to complete your order and deliver it to your doorstep.

Quality

The quality of our custom printed paper is premium and after processing the raw material, we give accurate design with minimum chances of error. We have micro scanners that scan each specification of custom printed paper for consistency.

Range

We have a wide range of paper types that include custom deli paper, wax paper, custom greaseproof paper, and much more. Moreover, you do not need to worry about the dimensions as we have standard to custom options for this.

Sustainable Solutions

We use high-quality kraft material and apply the relevant coating on it. Apart from paraffin wax, all our coatings are sustainable, even though we have a sustainable alternative too which is beeswax.

Innovation

Our company believes in innovation and strives for continual improvement which is why all our manufacturing facilities are avant-garde, unique, and highly efficient. These facilities help us in giving the best and the most accurate results.

Cost Savings

Considering the client's budget and understanding the customer's preference, our custom printed paper is a perfect blend of quality and cost-effectiveness. As we have all in-house manufacturing facilities that is why we easily cap the end cost of the product and deliver you at affordable rates.